Добро пожаловать на сайт Schneider Electric

Добро пожаловать на наш сайт.

MiCOM P111Enh Entry Range Overcurrent Relay, SW Version 1C, Manual (global file) P111Enh P111Enh/EN/M v1.3

Дата : 27/04/2016

Тип : Руководство пользователя

Языки : Английский

Версия : Global_2015_04_07_v1.4

Обозначение документа : P111Enh_EN_M

Дата : 27/04/2016

Тип : Руководство пользователя

Языки : Английский

Версия : Global_2015_04_07_v1.4

Обозначение документа : P111Enh_EN_M

Заголовок документа

Дата

Версия

Языки

Нужна помощь?

-

OVERCURRENT RELAY

MiCOM P111Enh Firmware 1C

Technical Manual (P111Enh/EN M v1.3) (28th January 2014)

-

Note: The technical manual for this device gives instructions

for its installation, commissioning, and operation. However, the

manual cannot cover all conceivable circumstances or include

detailed information on all topics. In the event of any questions

or specific problems arising, do not take any action without proper

authorization. Contact the appropriate Schneider Electric Energy

technical sales office and request the necessary information.Any agreements, commitments, and legal relationships and any

obligations on the part of Schneider Electric Energy including

settlements of warranties, result solely from the applicable

purchase contract, which is not affected by the contents of the

technical manual.This device MUST NOT be modified. If any modification is made

without the express permission of Schneider Electric Energy, it

will invalidate the warranty, and may render the product

unsafe.The SCHNEIDER ELECTRIC ENERGY logo and any alternative version

thereof are trademarks and service marks of SCHNEIDER ELECTRIC

ENERGY.MiCOM is a registered trademark of SCHNEIDER ELECTRIC ENERGY.

All trade names or trademarks mentioned herein whether registered

or not, are the sole property of their owners.This manual is provided for informational use only and is

subject to change without notice.2014, SCHNEIDER ELECTRIC ENERGY. All rights reserved.

-

CONTENTS

Safety Section P111Enh/EN SS

Update Documentation

Section 1 Introduction P111Enh/EN IT

Section 2 Technical Data P111Enh/EN TD

Section 3 Getting Started P111Enh/EN GS

Section 4 Settings P111Enh/EN ST

Section 5 Operation P111Enh/EN OP

Section 6 Application Notes P111Enh/EN AP

Section 7 Measurements and Recording P111Enh/EN MR

Section 8 Commissioning P111Enh/EN CM

Section 9 Maintenance P111Enh/EN MT

Section 10 Troubleshooting P111Enh/EN TS

Section 11 Symbols and Glossary P111Enh/EN SG

Section 12 Installation P111Enh/EN IN

Section 13 Communication Database P111Enh/EN CT

Section 14 Firmware and Service Manual Version History

P111Enh/EN VHTD

IT

ST

GS

OP

AP

MR

CM

MT

TS SG

IN

CT

N/A

SS

VH

-

Safety Section

P111Enh/EN SS v1.3

SS

SAFETY SECTION

-

Safety Section

P111Enh/EN SS v1.3 (SS) — 1

SS

CONTENTS

1. INTRODUCTION 2

2. HEALTH AND SAFETY 2

3. SYMBOLS AND LABELS ON THE EQUIPMENT 3

3.1 Symbols 3 3.2 Labels 3

4. INSTALLING, COMMISSIONING AND SERVICING 3

5. DE-COMMISSIONING AND DISPOSAL 6

6. TECHNICAL SPECIFICATIONS FOR SAFETY 6

6.1 Protective fuse rating 6 6.2 Protective class 6 6.3

Installation category 6 6.4 Environment 6 -

P111Enh/EN SS v1.3

Safety Section (SS) — 2

SS

STANDARD SAFETY STATEMENTS AND EXTERNAL LABEL INFORMATION FOR

SCHNEIDER ELECTRIC ENERGY EQUIPMENT1. INTRODUCTION This Safety Section and the relevant equipment

documentation provide full information on safe handling,

commissioning and testing of this equipment. This Safety Section

also includes reference to typical equipment label markings.The technical data in this Safety Section is typical only, see

the technical data section of the relevant equipment documentation

for data specific to a particular item of equipment.Before carrying out any work on the equipment the user should be

familiar with the contents of this Safety Section and the ratings

on the equipments rating label.Reference should be made to the external connection diagram

before the equipment is installed, commissioned or serviced.Language specific, self-adhesive User Interface labels are

provided in a bag for some equipment.2. HEALTH AND SAFETY The information in the Safety Section of

the equipment documentation is intended to ensure that equipment is

properly installed and handled in order to maintain it in a safe

condition.It is assumed that everyone who will be involved with the

equipment is familiar with the contents of this Safety Section, or

the Safety Guide (SFTY/4L M).When electrical equipment is in operation, dangerous voltages

are present in certain parts of the equipment. Failure to observe

warning notices, incorrect use, or improper use may endanger

personnel and equipment and also cause personal injury or physical

damage.Before working in the terminal strip area, the equipment must be

isolated.Proper and safe operation of the equipment depends on

appropriate shipping and handling, proper storage, installation and

commissioning, and on careful operation, maintenance and servicing.

For this reason only qualified personnel may work on or operate the

equipment.Qualified personnel are individuals who:

Are familiar with the installation, commissioning, and operation

of the equipment and of the system to which it is being

connected;Are able to safely perform switching operations in accordance

with accepted safety engineering practices and are authorized to

energize and de-energize equipment and to isolate, ground, and

label it;Are trained in the care and use of safety apparatus in

accordance with safety engineering practices;Are trained in emergency procedures (first aid).

The equipment documentation gives instructions for its

installation, commissioning, and operation. However, the manuals

cannot cover all conceivable circumstances or include detailed

information on all topics. In the event of any questions or

specific problems arising, do not take any action without proper

authorization. Contact the appropriate Schneider Electric Energy

technical sales office and request the necessary information. -

Safety Section

P111Enh/EN SS v1.3 (SS) — 3

SS

3. SYMBOLS AND LABELS ON THE EQUIPMENT For safety reasons the

following symbols which may be used on the equipment or referred to

in the equipment documentation, should be understood before it is

installed or commissioned.3.1 Symbols

Caution: refer to equipment documentation

Caution: risk of electric shock

Protective Conductor (*Earth) terminal

Functional/Protective Conductor (*Earth) terminal

Note: This symbol may also be used for a Protective Conductor

(Earth) Terminal if that terminal is part of a terminal block or

sub-assembly e.g. power supply.*NOTE: THE TERM EARTH USED THROUGHOUT THIS TECHNICAL MANUAL IS

THE DIRECT EQUIVALENT OF THE NORTH AMERICAN TERM GROUND.3.2 Labels

See Safety Guide (SFTY/4L M) for typical equipment labeling

information.4. INSTALLING, COMMISSIONING AND SERVICING

Equipment connections Personnel undertaking installation,

commissioning or servicing work on this equipment should be aware

of the correct working procedures to ensure safety. The equipment

documentation should be consulted before installing, commissioning,

or servicing the equipment. Terminals exposed during installation,

commissioning and maintenance may present a hazardous voltage

unless the equipment is electrically isolated. Any disassembly of

the equipment may expose parts at hazardous voltage, also

electronic parts may be damaged if suitable electrostatic voltage

discharge (ESD) precautions are not taken. If there is unlocked

access to the rear of the equipment, care should be taken by all

personnel to avoid electric shock or energy hazards. Voltage and

current connections should be made using insulated crimp

terminations to ensure that terminal block insulation requirements

are maintained for safety. Watchdog (self-monitoring) contacts are

provided in numerical relays to indicate the health of the device.

Schneider Electric Energy strongly recommends that these contacts

are hardwired into the substation’s automation system, for alarm

purposes. To ensure that wires are correctly terminated the correct

crimp terminal and tool for the wire size should be used. The

equipment must be connected in accordance with the appropriate

connection diagram. Protection Class I Equipment— Before energizing the equipment it must be earthed using the

protective conductor terminal, if provided, or the appropriate

termination of the -

P111Enh/EN SS v1.3

Safety Section (SS) — 4

SS

supply plug in the case of plug connected equipment. — The

protective conductor (earth) connection must not be removed

sincethe protection against electric shock provided by the equipment

would be lost.— When the protective (earth) conductor terminal (PCT) is also

used to terminate cable screens, etc., it is essential that the

integrity of the protective (earth) conductor be checked after the

addition or removal of such functional earth connections. For M4

stud PCTs the integrity of the protective (earth) connections

should be ensured by use of a locknut or similar.The recommended minimum protective conductor (earth) wire size

is 2.5 mm (3.3 mm for North America) unless otherwise stated in the

technical data section of the equipment documentation, or otherwise

required by local or country wiring regulations. The protective

conductor (earth) connection must be low-inductance and as short as

possible. All connections to the equipment must have a defined

potential. Connections that are pre-wired, but not used, should

preferably be grounded when binary inputs and output relays are

isolated. When binary inputs and output relays are connected to

common potential, the pre-wired but unused connections should be

connected to the common potential of the grouped connections.

Before energizing the equipment, the following should be

checked:— Voltage rating/polarity (rating label/equipment

documentation); — CT circuit rating (rating label) and integrity of

connections; — Protective fuse rating; — Integrity of the

protective conductor (earth) connection (whereapplicable); — Voltage and current rating of external wiring,

applicable to the application.Accidental touching of exposed terminals If working in an area

of restricted space, such as a cubicle, where there is a risk of

electric shock due to accidental touching of terminals which do not

comply with IP20 rating, then a suitable protective barrier should

be provided.Equipment use If the equipment is used in a manner not specified

by the manufacturer, the protection provided by the equipment may

be impaired.Removal of the equipment front panel/cover Removal of the

equipment front panel/cover may expose hazardous live parts, which

must not be touched until the electrical power is removed.UL and CSA listed or recognized equipment To maintain UL and CSA

approvals the equipment should be installed using UL and/or CSA

listed or recognized parts of the following type: connection

cables, protective fuses/fuse holders or circuit breakers,

insulation crimp terminals, and replacement internal battery, as

specified in the equipment documentation.Equipment operating conditions The equipment should be operated

within the specified electrical and environmental limits. -

Safety Section

P111Enh/EN SS v1.3 (SS) — 5

SS

Current transformer circuits Do not open the secondary circuit

of a live CT since the high voltage produced may be lethal to

personnel and could damage insulation. Generally, for safety, the

secondary of the line CT must be shorted before opening any

connections to it. For most equipment with ring-terminal

connections, the threaded terminal block for current transformer

termination has automatic CT shorting on removal of the module.

Therefore external shorting of the CTs may not be required, the

equipment documentation should be checked to see if this applies.

For equipment with pin-terminal connections, the threaded terminal

block for current transformer termination does NOT have automatic

CT shorting on removal of the module.External resistors, including voltage dependent resistors (VDRs)

Where external resistors, including voltage dependent resistors

(VDRs), are fitted to the equipment, these may present a risk of

electric shock or burns, if touched.Battery replacement Where internal batteries are fitted they

should be replaced with the recommended type and be installed with

the correct polarity to avoid possible damage to the equipment,

buildings and persons.Insulation and dielectric strength testing Insulation testing

may leave capacitors charged up to a hazardous voltage. At the end

of each part of the test, the voltage should be gradually reduced

to zero, to discharge capacitors, before the test leads are

disconnected.Insertion of modules and pcb cards Modules and PCB cards must

not be inserted into or withdrawn from the equipment whilst it is

energized, since this may result in damage.Insertion and withdrawal of extender cards Extender cards are

available for some equipment. If an extender card is used, this

should not be inserted or withdrawn from the equipment whilst it is

energized. This is to avoid possible shock or damage hazards.

Hazardous live voltages may be accessible on the extender card.External test blocks and test plugs Great care should be taken

when using external test blocks and test plugs such as the MMLG,

MMLB and MiCOM P990 types, hazardous voltages may be accessible

when using these. *CT shorting links must be in place before the

insertion or removal of MMLB test plugs, to avoid potentially

lethal voltages. *Note: When a MiCOM P992 Test Plug is inserted

into the MiCOM P991 Test Block, the secondaries of the line CTs are

automatically shorted, making them safe.Fiber-optic communication Where fiber-optic communication

devices are fitted, these should not be viewed directly. Optical

power meters should be used to determine the operation or signal

level of the device.Cleaning The equipment may be cleaned using a lint free cloth

dampened with clean water, when no connections are energized.

Contact fingers of test plugs are normally protected by petroleum

jelly, which should not be removed.Maintenance and installation For safety reason, no work must be

carried out on the P111Enh until all power sources to the unit have

been disconnected -

P111Enh/EN SS v1.3

Safety Section (SS) — 6

SS

5. DE-COMMISSIONING AND DISPOSAL

De-commissioning The supply input (auxiliary) for the equipment

may include capacitors across the supply or to earth. To avoid

electric shock or energy hazards, after completely isolating the

supplies to the equipment (both poles of any dc supply), the

capacitors should be safely discharged via the external terminals

prior to de-commissioning.Disposal It is recommended that incineration and disposal to

water courses is avoided. The equipment should be disposed of in a

safe manner. Batteries should be removed from any equipment before

its disposal, taking precautions to avoid short circuits.

Particular regulations within the country of operation, may apply

to the disposal of the equipment.6. TECHNICAL SPECIFICATIONS FOR SAFETY Where UL Listing of the

equipment is not required the recommended fuse type is a high

rupture capacity (HRC) type with a maximum current rating of 16

Amps and a minimum DC rating of 250 Vdc, for example the Red Spot

NIT or TIA type.To maintain UL and CUL Listing of the equipment for North

America a UL Listed fuse shall be used. The UL Listed type shall be

a Class J time delay fuse, with a maximum current rating of 15 A

and a minimum DC rating of 250 Vdc, for example type AJT15.The protective fuse should be located as close to the unit as

possible.6.1 Protective fuse rating

DANGER — CTs must NOT be fused since open circuiting them may

produce lethal hazardous voltages.6.2 Protective class

IEC 60255-27: 2005 Class I (unless otherwise specified in the

equipment documentation). .6.3 Installation category

IEC 60255-27: 2005 Installation category III (Overvoltage

Category III):EN 60255-27: 2005 Distribution level, fixed installation.

Equipment in this category is qualification tested at 5 kV peak,

1.2/50 s, 500 , 0.5 J, between all supply circuits and earth and

also between independent circuits.6.4 Environment

The equipment is intended for indoor installation and use only.

If it is required for use in an outdoor environment then it must be

housed in a specific cabinet which will enable it to meet the

requirements of IEC 60529 with the classification of degree of

protection IP54 (dust and splashing water protected).Pollution Degree — Pollution Degree 2 Compliance is demonstrated

by reference to safety Altitude — Operation up to 2000 m

standards.IEC 60255-27:2005

EN 60255-27: 2005

-

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh

IT

INTRODUCTION

Date: 28th January 2014 Hardware Suffix: A Software Version: 1C

Connection Diagrams: 10P111Enh02 -

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh (IT) 1-1

IT

CONTENTS

1. MICOM DOCUMENTATION STRUCTURE 3

2. INTRODUCTION TO MICOM 5

3. PRODUCT SCOPE 6 3.1 Key for the manual 6 3.2 Functional

overview 63.3 Protection functions suitable for low voltage 8

3.3.1 Low voltage earthing systems 8

3.3.2 Capatibility of MiCOM low voltage protection function

93.4 Ordering options Information (Required with Order ) 10

FIGURES

Figure 1: Functional diagram of the P111Enh 8

-

P111Enh/EN IT v1.3

Introduction (IT) 1-2 MiCOM P111Enh

IT

-

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh (IT) 1-3

IT

1. MiCOM DOCUMENTATION STRUCTURE The manual provides a

functional and technical description of the MiCOM protection relay

and a comprehensive set of instructions for the relays use and

application.The section contents are summarized below:

P111Enh/EN IT Introduction

A guide to the MiCOM range of relays and the documentation

structure. Also a general functional overview of the relay and

brief application summary are given.P111Enh/EN TD Technical Data

Technical data including setting ranges, accuracy limits,

recommended operating conditions, ratings and performance data.

Compliance with norms and international standards is quoted where

appropriate.P111Enh/EN GS Getting Started

A guide to the different user interfaces of the protection relay

describing how to start using it. This section provides detailed

information regarding the communication interfaces of the relay,

including a detailed description of how to access the settings

database stored within the relay.P111Enh/EN ST Settings

List of all relay settings, including ranges, step sizes and

defaults, together with a brief explanation of each setting.P111Enh/EN OP Operation

A comprehensive and detailed functional description of all

protection and non-protection functions.P111Enh/EN AP Application Notes

This section includes a description of common power system

applications of the relay, calculation of suitable settings, some

typical worked examples, and how to apply the settings to the

relay.P111Enh/EN MR Measurements and Recording

Detailed description of the relays recording and measurements

functions.P111Enh/EN CM Commissioning

Instructions on how to commission the relay, comprising checks

on the calibration and functionality of the relay.P111Enh/EN MT Maintenance

A general maintenance policy for the relay is outlined.

P111Enh/EN TS Troubleshooting

Advice on how to recognize failure modes and the recommended

course of action. Includes guidance on whom at Schneider Electric

Energy to contact for advice.P111Enh/EN SG Symbols and Glossary

List of common technical abbreviations found within the product

documentation.P111Enh/EN IN Installation

Recommendations on unpacking, handling, inspection and storage

of the relay. A guide to the mechanical and electrical installation

of the relay is provided, incorporating earthing recommendations.

All external wiring connections to the relay are indicated. -

P111Enh/EN IT v1.3

Introduction (IT) 1-4 MiCOM P111Enh

IT

P111Enh/EN CM Communication Database

This section provides an overview regarding the SCADA/DCS

communication interfaces of the relay.P111Enh/EN VH Firmware and Service Manual Version History

History of all hardware and software releases for the

product. -

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh (IT) 1-5

IT

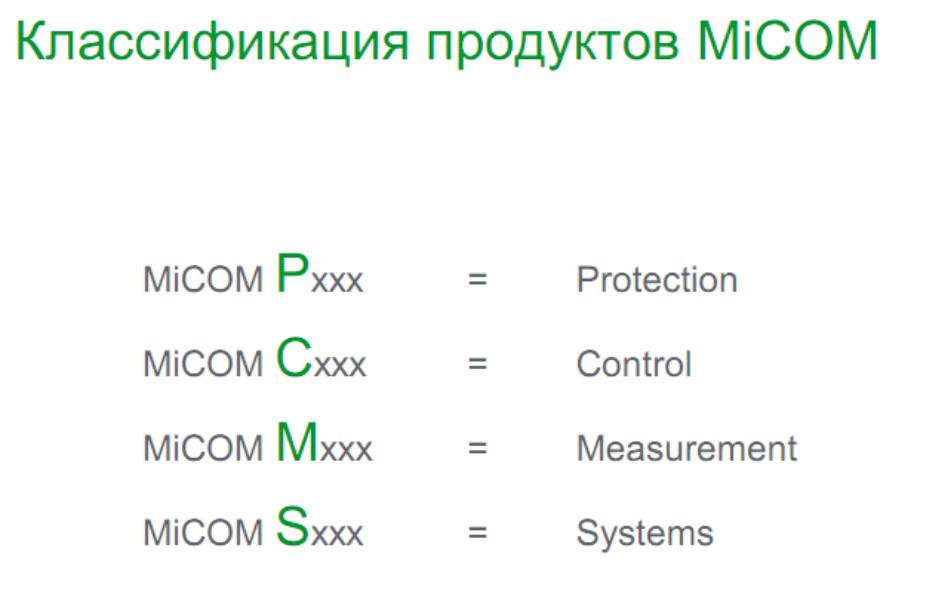

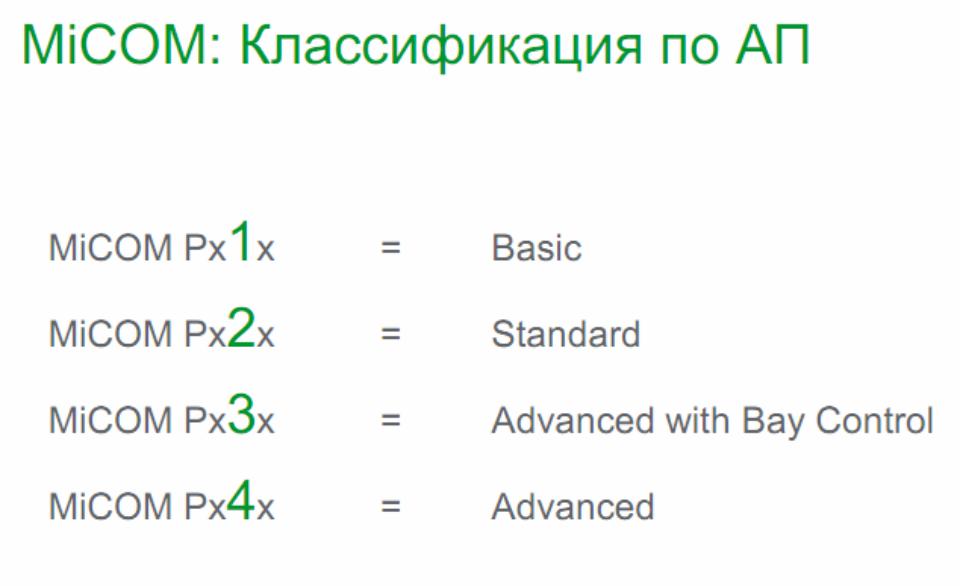

2. INTRODUCTION TO MiCOM MiCOM is a comprehensive solution

capable of meeting all electricity supply requirements. It

comprises a range of components, systems and services from

Schneider Electric Energy.Central to the MiCOM concept is flexibility.

MiCOM provides the ability to define an application solution

and, through extensive communication capabilities, integrate it

with your power supply control system.The components within MiCOM are:

P range protection relays;

C range control products;

M range measurement products for accurate metering and

monitoring;S range versatile PC support and substation control

packages.MiCOM products include extensive facilities for recording

information on the state and behavior of the power system using

disturbance and fault records. They can also provide measurements

of the system at regular intervals for a control center enabling

remote monitoring and control to take place.For up-to-date information on any MiCOM product, visit our

website:www.schneider-electric.com

http://www.areva-td.com/

-

P111Enh/EN IT v1.3

Introduction (IT) 1-6 MiCOM P111Enh

IT

3. PRODUCT SCOPE The P111 is a 3 phase and earth fault

non-directional overcurrent protection relay which has been

designed to control, protect and monitor industrial and

distribution installations. Refer to section 3.2.The scope of P111 applications includes:

industry and distribution LV networks (refer to 3.3. Protection

functions suitable for low voltage section in this chapter)industry and distribution MV and HV networks,

back-up protection in HV applications.

The relay protects one, two or three-phase applications against

earth fault and phase-to-phase short-circuit faults. Thanks to a

built-in USB port, disturbance records (selected models), fault

records, events and relay settings can be downloaded to a local PC

(selected Models).Settings for the protection elements are entered using the front

panel keyboard and can be checked on the local display or using the

MiCOM S1 or S1 Studio setting software (selected Models).3.1 Key for the manual

The P111Enh relays are available in several hardware versions

offering different numbers of outputs, inputs, communication ports

etc. called Models (Model: L, N, A, B, E).Please refer to the commercial publication for further

information on the product features and application

arrangements.3.2 Functional overview

The P111Enh relay offers a wide variety of protection functions.

The protection features are summarized below:PROTECTION FUNCTIONS OVERVIEW Function available

50/51

Three non-directional overcurrent stages are provided for each

phase. The first (I>) and the second stage (I>>) may be

set to Inverse Definite Minimum Time (IDMT) or Definite Time (DT);

the third stage (I>>>) may be set to DT only.All models

50N/51N

Three non-directional overcurrent stages are provided. The first

stage (IN>) may be set to Inverse Definite Minimum Time (IDMT)

or Definite Time (DT); the second and third stage (IN>> and

IN>>>) may be set to DT only.All models (IN>>>:E only)

SOTF Switch On To Fault Phase Overcurrent Stage. A,B,E

BOL

The Blocked Overcurrent Logic is available for each protection

element. This consists of a start signal and protection block timer

that can for instance be used to implement busbar blocking

schemes.A,B,E

SOL

The Selective Overcurrent Logic provides the capability of

temporarily altering (i.e. lengthen) the time-delay settings for

stages 2 and 3 of the phase overcurrent and earth fault

elements.E

46 One stage is provided to be used as backup protection for

both phase-to-earth and phase-to-phase faults. E49 RMS thermal overload (single time constant) protection with

thermal characteristics, suitable for both cables and transformers.

Both Alarm and trip stages are provided.N,A,B,E

-

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh (IT) 1-7

IT

PROTECTION FUNCTIONS OVERVIEW Function available

46BC Broken conductor (open jumper) used to detect open circuit

faults using the I2/I1 ratio. E50BF Circuit breaker failure element with undercurrent

detection. All models79 Four-shot three-pole auto-recloser with external initiation

and sequence coordination capability. ESecond harmonic blocking that can be associated with all the

protection elements. A, EUSB port (in models: A,B,E with powering feature) N,A,B,E

Rear communication port (RS485) L(optional), N,A,B,E

CB Control via a rear communication port (RS485) or dedicated

binary input A,B,EBinary inputs L(0), A(4), B(4), E(8)

Output contacts (Watchdog included) L(4), N(6), A(8), B(4),

E(6)

4 timers (AUX) A,B,E

Comprehensive disturbance recording (waveform capture) A,E

Time synchronization via binary input B,E

Circuit breaker status & condition monitoring A, E

Nominal current (In and Ien) 1A or 5A switchable in menu All

modelsThe P111Enh also offers the following relay management functions

in addition to the functions listed above.Up to 20 Fault Records, 5 Alarm Records, 200 Events (if ports

are available) (when the available space is exhausted, the oldest

record is automatically overwritten by the new one)Readout of actual settings available via the USB port or rear

communication port (RS485) (if ports are available)2 alternative setting groups

3 phase current inputs

Earth fault current input

CB Control via the front panel menu

Counters

Programmable allocation of binary inputs and outputs

Multi-level password protection

-

P111Enh/EN IT v1.3

Introduction (IT) 1-8 MiCOM P111Enh

IT

Application overview

Figure 1: Functional diagram of the P111Enh

3.3 Protection functions suitable for low voltage

3.3.1 Low voltage earthing systems

There are 4 low voltage (LV) earthing systems designated by a 2

or 3-letter acronym:TN-S

TN-C

TT

IT

The letters making up the acronym have the following

meanings:Letter Meaning

First letter Transformer neutral point

I Earthed with an impedance

T Directly earthed

Second letter Electrical exposed conductive parts of the

consumerT Earthed

N Connected to the neutral conductor

Third letter (optional) Protective Earth conductor

S Separate N neutral conductor and PE Protective Earth

conductorC Combined N neutral conductor and PE Protective Earth conductor

(PEN)Output Relays: RL6-RL7

I, IN

Fault recording:20

Setting software S1

or Studio

USB port

Rear port

Event recording:200

(Model L: optional)

LEDs: 8

Disturbance Recorder: up to 3s

RS485 portfor DCS system

(Model L: optional)

Recording features I/O features

Binary Inputs: L5-L8

Output Relays: RL4-RL5

— 2 Setting Groups- Self Diagnostic- CB Close/Trip via HMI- Cold

Load Pick-upMEASUREMENTS

50/51 50N51N

49 4646BC50BF 79

86

Alarm recording:5

Counters

Outputs Relay: RL1-RL3, WD

Close and Trip functional keys

— Blocking Logic- 4 Auxiliary Timers- SOFT (Switch on to

fault)AUXILIARY FUNCTIONS

— CB mechanical operation counter

— Phase current- Residual current- Trip, start, alarm counters-

In (Ion) 1A/5A switchable in menuFunction available in all Models (L, N, A, B, E)

Function available in Models: N, A, E only

Function available in Model E only

16×2 alphanumerical LCD displayCB

— Selective Scheme Logic- Time Synchronisation via Binary

Input— Auto-reclose counters- Negative and positive sequence

currentsFunction available in Models: A, B, E only

Binary Inputs: L1-L4

PJ101ENd

Function available in Model A only

Function available in Models: A, E only

— Inrush blocking (2nd harm.)- CB Local/Remote Mode- CB

Monitoring- Relay Maintenance ModeFunction available in Models: N, A, B, E only

-

Introduction

P111Enh/EN IT v1.3 MiCOM P111Enh (IT) 1-9

IT

3.3.2 Capatibility of MiCOM low voltage protection function

MiCOM protection function can be used with low voltage (LV) as

long as the conditions below are met:The distribution circuit must be rated higher than 32A

The installation must comply with standard IEC 60364.

For additional information about the compability of MiCOM

protection functions with low voltage, please contact Schneider

Electric technical support.The table below lists the MiCOM protection functions suitable

for low voltage according to earthing system used. MiCOM protection

functions not listed in this table are not suitable for low

voltage. The protection functions listed in this table are

available according to the MiCOM type.Protection ANSI code Earthing system

Comments TN-S TN-C TT IT

Phase overcurrent 50/51 Neutral conductor not protected Earth

fault /Sensitive earth fault 50N/51N (1)Earth fault /Sensitive earth fault 50G/51G (3)

Negative sequence /unbalance 46 Threshold to be

adopted to the phase unbalance

Thermal overload for cables /capacitors /transformer / generic

49RMSNeutral conductor not protected

Restricted earth fault 64REF (3) Two-winding transformer

differential87T

Directional phase overcurrent 67 (4) (4)

Directional earth fault 67N/67NC Incompability with LV diagrams

(4-wire) Directional active overpower 32P (2) (2)Directional reactive overpower 32Q (2) (2)

Under-voltage (L-L or L-N) 27

Remanent overvoltage 27R

Over-voltage (L-L or L-N) 59

Neutral voltage displacement 59N (4) (4) Residual voltage not

available with 2 VTs Negative sequence over-voltage 47Over-frequency 81H

Under-frequency 81L

Rate of change of frequency 81R

Synchro-check 25 : Protection function suitable for low voltage

(according to MiCOM) (1) : Not recommended even on the second fault

(2) : 2-wattmeter method not suitable for unbalanced loads (3) :

Residual current too low in IT (4) : 2 phase-to-phase VTs -

P111Enh/EN IT v1.3

Introduction (IT) 1-10 MiCOM P111Enh

IT

3.4 Ordering options Information (Required with Order)

P111Enh Overcurrent Protection P111 1 N N N N 1

Three Phase Overcurrent and Earth Fault Protection. 2×16 LCD

display 5), Flush mounting case, USB front port 4) (not available

in model L), 8 LEDs, 4 current inputs Close and Trip keys on the

front panel Real time clock 6)Model

Enhanced Model L ( no Binary Inputs, 4 Binary Outputs) L

Enhanced Model N ( no Binary Inputs, 6 Binary Outputs) N

Enhanced Model B (4 Binary Inputs, 4 Binary Outputs) 1) B

Enhanced Model A (4 Binary Inputs, 8 Binary Outputs) A

Enhanced Model E (8 Binary Inputs, 6 Binary Outputs) 1) E

Case type (mounting)

Standard flush-mounting case 1

Earth current input

Ion = 1 A/5A (selectable via HMI); 0.01 2 Ion Ion = 1 A/5A

(selectable via HMI); 0.05 12 Ion Ion = 1 A/5A (selectable via

HMI); 0.01 12 Ion 3)0 3 4

Phase current inputs

In=1A/5A , (selectable via HMI); 0.1 40 In 9

Vx Auxiliary Voltage Supply

Model A, B, E: 24 — 60 Vac/dc 2) Model L, N: 24 240 Vac/250 Vdc;

Model A, B, E: 90 — 240 Vac/250 Vdc;1 2

Type of binary inputs; Auxiliary voltage range for binary

inputsStandard; Voltage range as for Vx auxiliary voltage supply (see

above) NCommunication port / protocol

Model L: Without USB port and RS485 Model L 1),N,B,A,E: USB port

4) and RS485 with settable switching between Modbus or IEC103 via

HMI0 1

Language

English /German/ French/ Spanish / Russian / Turkish / Regional

(Polish) 1Application

Standard 1

P111Enh accessories

Without Wall mounting case adaptor

N S

NOTES: 1) Model available in selected countries only 2) This

option is not available for model N and L, because these models

have increased Vx range(24-240 Vac/250 Vdc) for option 2 3) This hardware version is

available in selected countries only 4) In Model N USB port has not

P111Enh supplying facilities 5) In Model L and N LCD has no

back-lit feature 6) In Model L and N have no backup capacitor to

support RTC. Typical support time for break inauxiliary voltage powering is 60s.

-

Technical Data

P111Enh/EN TD v1.3 MiCOM P111Enh

TD

TECHNICAL DATA

Date: 28th January 2014 Hardware Suffix: A Software Version: 1C

Connection Diagrams: 10P111Enh02 -

P111Enh/EN TD v1.3

Technical Data MiCOM P111Enh

TD

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-1

TD

CONTENT

1. Mechanical specification 3

1.1 Case 3 1.2 Terminals 3

2. RATINGS 4

2.1 Power Supply 4 2.2 Frequency (Current Inputs) 5 2.3 Current

Inputs 5 2.4 Binary Inputs 6 2.5 Output Relay Characteristics 73. INSULATION 8

4. EMC TESTS 9

5. ENVIRONMENT 10

6. EU Directive 11

6.1 EMC Compliance 11 6.2 Product Safety 11

7. DEVIATIONS OF THE PROTECTION ELEMENTS 12

8. Deviations of Automation Functions Timers 13

9. DEVIATIONS OF MEASUREMENTS 13

10. PROTECTION SETTING RANGES 14

10.1 [50/51] Phase Overcurrent 14 10.1.1 Protection Setting

Ranges 14 10.2 Switch on to fault (SOTF) (Model A, B, E ) 15 10.2.1

Protection Setting Ranges 15 10.3 [49] Thermal Overload Protection

(Model N, A, B, E ). 15 10.3.1 Protection Setting Ranges 15 10.4

[50N/51N] Earth fault protection 16 10.4.1 Protection Setting

Ranges 16 10.5 Negative Sequence Overcurrent Protection (Model E ).

17 10.5.1 Protection Setting Ranges 17 10.6 [46BC] Broken Conductor

Protection (Model E ). 17 10.6.1 Protection Setting Ranges 17 10.7

[50BF] CB Fail Protection 18 10.7.1 Protection Setting Ranges 18

10.8 Multishot Autoreclose Function (Model E ). 19 10.8.1 Multishot

auto-recloser Settings 19 -

P111Enh/EN TD v1.3

Technical Data (TD) 2-2 MiCOM P111 Enh

TD

10.8.2 Further Time-delays 20

11. AUTOMATION CONTROL FUNCTIONS 21

11.1 Trip Commands 21 12.1 Latch Functions 21 12.2 Blocking

Logic 21 12.3 Inrush blocking Logic (Model A and E ) 22 12.4 Logic

Selectivity (Model E ) 22 12.5 Output Relays 22 12.6 Latch of the

auxiliary Output Relays 22 12.7 Reverse Output Relay Logic 22 12.8

Inputs (Model A, B and E ) 23 12.8.1 Input Assignation 23 12.8.2

Reverse Input Logic 23 12.9 LEDs 23 12.10 Latch of the auxiliary

Output Relays 23 12.11 Auxiliary Timers (available in B, A and E )

24 12.12 Cold Load Pickup 24 12.13 Circuit Breaker 25 12.13.1 CB

Time Setting Ranges 25 12.13.2 Time-delay for Faulty CB External

Signal (Model A, B and E ) 25 12.13.3 Remote Control Mode (Model A

and E ) 25 12.13.4 Unblock SOTF Time pulse after CB Close (Model A

, B and E ) 25 12.13.5 Trip Circuit Supervision Setting Ranges

(Model A and E ) 25 12.13.6 Circuit Breaker Control and Monitoring

Setting Ranges (Model A and E ) 2513. RECORDING FUNCTIONS 26

13.1 Event Records 26 13.2 Fault Records 26 13.3 Instantaneous

Recorder (Model E ) 2613.4 Alarm Recorder 2613.5 Disturbance

Records (Model A and E ) 27 13.5.1 Triggers, Data, Setting Ranges

2714. COMMUNICATION (in Model L : option) 28

15. CURVES 29

15.1 General 29 15.1.1 Inverse Time Curves 29 15.1.2 Reset Timer

30 15.2 Thermal Overload Curves 32 -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-3

TD

1. Mechanical specification 1.1 Case

Design Flush mounting case

Weight approx. 0.5 kg 1.2 Terminals

AC Current Input Terminals

Threaded M3 screw-type plug-in terminals, with wire protection

for conductor cross-section(i) 0.2 — 6 mm2 single-core

(ii) 0.2 — 4 mm2 finely stranded

General Input/Output Terminals

For power supply, binary and contact inputs, output contacts and

COM for rear communications.Threaded M3 screw-type plug-in terminals, with wire protection

for conductor cross-section(i) 0.2 — 4 mm2 single-core

(ii) 0.2 — 2.5 mm2 finely stranded

Local communication

USB port

Cable Type: USB 2.0

Connectors:

PC: type A male

P111Enh: type mini B 5-pin male

USB Cable: minimum 1P*28AWG/2C*24AWG, max : 2m

Rear Communications Port

EIA(RS)485 signal levels, two wire

Connections located on general purpose block, M3 screw

For screened twisted pair cable, distance to be bridged:

multi-endpoint link: max. 100 mIsolation to SELV level.

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-4 MiCOM P111 Enh

TD

2. RATINGS 2.1 Power Supply

Nominal auxiliary voltage Vx (ordering options)

24 60 Vdc/ 24 60 Vac (50/60 Hz) 90 250 Vdc/ 90 240 Vac (50/60

Hz) 24 250 Vdc/ 24 240 Vac (50/60 Hz) (L and N )Operating range 19 72 V (dc), 19 66 V (ac) 71 300 V (dc), 71 265

V (ac) 19 300 Vdc/ 19 265 Vac (50/60 Hz) (L and N )Tolerable AC ripple Up to 12% for a dc supply, per IEC 60255-11:

2008Nominal Burden Auxiliary Power Supply Vx

Note: (i) Initial position: no output nor LED energized.

(ii) Active position: all outputs and LEDs energized.

For AC max. approx.:

Vx range

Vx S

V VA

Initial position Active position

24 60 Vac 24 2.5 4.5

48 3.0 5.5

90 240 Vac (L, N : 24 -240Vac)

110 4.0 6.5

220/230 6.0 9.0

264 7.0 10.0

For dc Vx voltage max. approx:

Vx range

S

W

Initial position Active position

24 60 Vdc 1.5 3.5

90 240 Vdc 2.0 3.5

Auxiliary Power Supply Voltage Interruption

IEC 60255-11: 2008

Within the auxiliary supply range: — 90-250Vdc, the relay will

withstand a 50 ms; — 24-48Vdc, the relay will withstand a 20 ms;

Interruption of the DC auxiliary supply without de-energizing.EN 61000-4-11: 1997

Within the auxiliary supply range: — 90-250Vac, the relay will

withstand a 50 ms; — 24-48Vac, the relay will withstand a 20 ms;

Interruption of the AC auxiliary supply without de-energizing.Power-up Time for Auxiliary Supply Voltage only

Time to power up via auxiliary supply: < 0.5s

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-5

TD

2.2 Frequency (Current Inputs)

Nominal frequency 50 or 60 Hz (selectable in P111Enh menu)

2.3 Current Inputs

Phase current inputs:

Nominal current (In) 1 or 5 A (selectable via HMI)

RMS measurement in range 40 Hz 1 kHz

Fundamental harmonic measurement in range

40 Hz 70 Hz

Operating range 0.1 40 In Nominal Burden at In < 0.3 VA at

In=5A; < 0.1 VA at In=1A;Thermal withstand 1 s @ 100 x rated current 2 s @ 40 x rated

current 10 s @ 30 x rated current continuous: 4 x rated currentConnection Refer to section 12 of P111Enh Installation chapter

(P111Enh/EN IN)Current transformer requirements

Detailed information and CT requirements are given in the

Application chapter (P111Enh/EN AP)Earth current inputs:

Ion: earth fault input nominal current (Ien)

Nominal current (Ien): 1 or 5 A (selectable via HMI)

Fundamental harmonic measurement in range

40 Hz 70 Hz

Operating range Selected at order (Cortec): 0.01 2Ion 0.05 12Ion

0.01 12Ion (special version for some regions only)Nominal Burden at Ion < 0.3 VA at In=5A; < 0.1 VA at

In=1A;Thermal withstand 1 s @ 100 x rated current 2 s @ 40 x rated

current 10 s @ 30 x rated current continuous @ 4 x rated

currentConnection Refer to section 12 of P111Enh Installation chapter

(P111Enh/EN IN)Current transformer requirements

Detailed information and CT requirements are given in the

Application chapter (P111Enh/EN AP)Detailed information about CT requirements are given in the

Application chapter (P111Enh/EN AP) -

P111Enh/EN TD v1.3

Technical Data (TD) 2-6 MiCOM P111 Enh

TD

2.4 Binary Inputs

Binary inputs type: Optically isolated inputs

Binary input energy consumption Logic input burden for Vx

ordering code 0 R imput = approx. 6kOhmLogic input burden for Vx ordering code 1 R imput = approx.

109kOhmLogic input recognition time As filtering time + 2 ms

Ordering Code of

Vx

Filtering time

approx.

Binary Inputs

Nominal Voltage range

Voltage operating range

Minimum polarisation

voltage (Logic 1) approx.

Maximum polarisation

current approx.

Maximum continuous withstand

1 20 ms 24 60 Vac/dc 19.2 66 Vac/dc 16 Vdc 18 Vac 12 mA

(66V)110 Vdc 78 Vac

2 20ms 90 240 Vac/dc 71 264 Vac/dc 66 Vac/dc 2.5 mA (264V)

300 Vdc 264 Vac

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-7

TD

2.5 Output Relay Characteristics

Contact ratings

Contact relay Dry contact, Ag Ni

Carry capability 5 A continuous

Rated Voltage 250 Vac

Breaking characteristics for RL1, RL3 and WD

Short-duration capacity 25 A for 3 s

Making capacity 150 A for 30 ms

AC breaking capacity 1250 VA resistive (cos = unity) 1250 VA

inductive (cos = 0.7)DC breaking capacity 250 Vdc; 50 W resistive 25 W inductive (L/R

= 40 ms)Operation time

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-8 MiCOM P111 Enh

TD

3. INSULATION

Insulation resistance EN 60255-5: 2001 > 500 M at 500 Vdc

(Using only electronic/brushless insulation tester).High Voltage (Dielectric) Withstand

EN 60255-27: 2005 2 kV rms AC, 1 minute: Between all case

terminals connected together and the case earth. Between all

terminals of independent circuits with terminals on each

independent circuit connected together.Impulse Voltage Withstand Test

EN 60255-27:2005 Front time: 1.2 s, Time to half-value: 50 s,

Peak value: 5 kV Source Characteristics: 500 Ohm, 0.5 J. Common and

differential mode: power supply, terminal block (excluding RS485),

binary inputs, relaysCreepage Distances and Clearances

EN 60255-27:2005 Pollution degree 2, Overvoltage category III,

Impulse test voltage 5 kV. -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-9

TD

4. EMC TESTS

1 MHz Burst High Frequency Disturbance Test

EN 60255-22-1: 2008 Class III

Common-mode test voltage: 2.5 kV, Differential test voltage: 1.0

kV, Test duration: 2 s, Source impedance: 200Immunity to Electrostatic Discharge

EN 60255-22-2: 2008 Class 3

8 kV discharge in air to all communication ports. 6 kV point

contact discharge to any part of the front of the product.Electrical Fast Transient or Burst Requirements

EN 60255-22-4: 2008 Test severity Class III

Amplitude: 2 kV, Burst frequency 5 kHz (Class III)

Surge Immunity Test EN60255-22-5: 2002; EN 61000-4-5: 2006,

Level 3Time to half-value: 1.2/50 s, Amplitude: 2 kV between all groups

and case earth, Amplitude: 1 kV between terminals of each groupImmunity to Radiated Electromagnetic Energy

EN 60255-22-3: 2008, Class III:

Test field strength, frequency band: — 80 MHz to 1000 MHz: 10

V/m, — 1.4 GHz to 2.7 GHz: 10 V/m Test using AM: 1 kHz / 80%

sinusANSI C37.90.2: 2004 20V/m 80MHz-1GHz, 80% AM, 1kHz sinus, 20V/m

80% AM at 80MHz, 160MHz, 450MHz, 900MHz 20V/m, 900MHz 200Hz 50%

pulse with modulationRadiated Immunity from Digital Radio Telephones

EN 60255-22-3:2008

10 V/m, 900 MHz 100% AM, 200 Hz/50% square wave

Immunity to Conducted Disturbances Induced by Radio Frequency

FieldsEN 61000-4-6: 2009, Level 3

Disturbing test voltage: 10 V, 150 Hz to 80 MHz, 80% AM, 1

kHzPower Frequency Magnetic Field Immunity

EN 61000-4-8: 2010, Level 4

30 A/m applied continuously, 300 A/m applied for 3 s

Conducted Emissions EN 55022: 2010 0.15 — 0.5 MHz, 79 dBV (quasi

peak) 66 dBV (average); 0.5 — 30 MHz, 73 dBV (quasi peak) 60 dBV

(average)Radiated Emissions EN 55022: 2010 30 — 230 MHz, 40 dBV/m at 10 m

measurement distance; 230 — 1 GHz, 47 dBV/m at 10 m measurement

distanceLogic Inputs at power frequency

IEC 61000-4-16 Level 4 IEC 60255-22-7

300V MC, 150 MD

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-10 MiCOM P111 Enh

TD

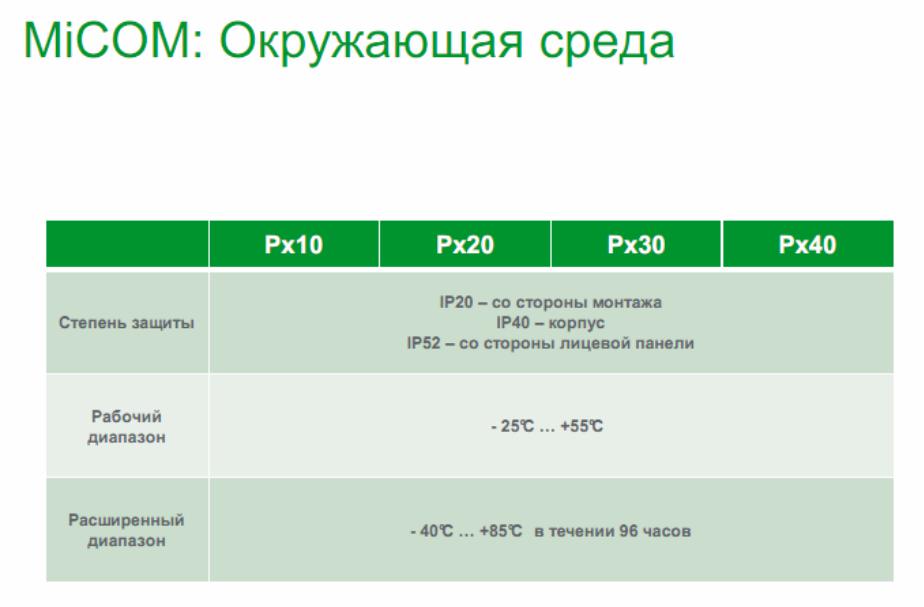

5. ENVIRONMENT

Ambient Temperature Range

EN 60255-1: 2010 Operating temperature range: -20C to +60C (4F

to +140F), Temporarily permissible temperature: 40C to +85C (40F to

+185F) with double errors Storage and transit: 25C to +70C (13F to

+158F).Ambient Humidity Range

EN 60068-2-78: 2001 56 days at 93% relative humidity and

+40C.EN 60068-2-30: 2005 Damp heat cyclic, six (12 + 12) hour cycles,

93% RH, +25 to +55CCorrosive Environments

IEC 60068-2-60: 1995 Part 2, Test Ke, Flowing mixed gas

corrosion test, Method (class) 4Industrial corrosive environments/poor environmental control,

mixed gas flow test. 21 days at 75% relative humidity and 25C

Exposure to elevated concentrations of H2S(10ppb), CL2 (10ppb), NO2

(200ppb), SO2 (200ppb)Vibration Test EN 60255-21-1: 1995 Response Class 1 Endurance

Class 1Shock and Bump

EN 60255-21-2: 1995 Shock response Class 1 Shock withstand Class

1 Bump Class 1Seismic EN 60255-21-3:1995 Class 2

Enclosure Protection

EN 60529: 1991

IP 40 Protection for relay housing IP 20 Protection for

terminals. IP 54 Protection (front panel) against dust and dripping

water for flash mounted case. -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-11

TD

6. EU Directive 6.1 EMC Compliance

2004/106/EC

Compliance with the European Commission’s EMC Directive.

Product Specific Standards were used to establish

conformity:EN 60255-26: 2009

EN 60255-1: 2010

6.2 Product Safety

2006/95/EC

Compliance with the European Commission’s Low Voltage Directive.

Compliance is demonstrated by reference to generic safety

standards:EN60255-27:2005

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-12 MiCOM P111 Enh

TD

7. DEVIATIONS OF THE PROTECTION ELEMENTS Glossary

I : Phase current

Is : setting value for I>, I>>, I>>>, SOTF

I2 : I2>

Ies : setting value for IN_1 (IN>), IN_2 (IN>>), IN_3

(IN>>>)Ien ,Ion: Earth fault current input nominal current

DT : Definite time

IDMT : Inverse definite minimum time

TYPICAL OPERATION TIME (protection time-delay set to 0 ms)

Operation time: All types of faults 40ms

PROTECTION ACCURACY

Element Range Deviation Trigger Reset Time deviation

Phase overcurrent elements (I> & I>> &

I>>> & SOTF)0.1 to 40 In 5% 0.01In DT: Is 5% 0.01In IDMT: 1.1Is 5%

0.01In0.95 Is 5% 0.01In 1.05 Is 5% 0.01In

2% +2050 ms 5% +2050 ms

Earth fault overcurrent elements (IN_1 & I N_2 &

IN_3)0.01 to 2Ien 0.05 to 12 Ien 0.01 to 12 Ien

5% 0.002 Ien 5% 0.005 Ien 5% 0.004 Ien

DT: Ies 5% 0.002 Ien Ies 5% 0.005 Ien Ies 5% 0.004 Ien

0.95 Ies Ies 5% 0.002 Ien Ies 5% 0.005 Ien Ies 5% 0.004 Ien

2% +2050 ms

0.01 to 2Ien 0.05 to 12 Ien 0.01 to 12 Ien

5% 0.002 Ien 5% 0.005 Ien 5% 0.004 Ien

IDMT: 1.1Ies Ies 5% 0.002 Ien Ies 5% 0.005 Ien Ies 5% 0.004

Ien1.05 Ies Ies 5% 0.002 Ien Ies 5% 0.005 Ien Ies 5% 0.004 Ien

5% +2050 ms

Negative sequence phase overcurrent elements (I2>)

0.1 to 4 In 5% 0.01In DT: Is 5% Is 2%0.01In IDMT: 1.1Is

5%0.01In0.95 Is 5% 0.01In 1.05 Is 5% 0.01In

2% +2050 ms 5% +2050 ms

Broken conductor (I2/I1).

20 to 100% 5% 0.01In DT: Is 5% 0.01In 0.95 Is 5% 0.01In

5% +2050 ms

Thermal overload (Itherm, Alarm, Trip)

0.10 to 3.0 In 5% 0.01In Itherm 5% 0.01In 0.97 Itherm

5%0.01In5% +2050 ms (ref. IEC 60255-8)

Note: For e/f settings below 0.1In it is strongly recommend to

use screened cable between e/f CT and P111Enh terminals. Without

using screened cable the accuracy can be worse than given in the

table above (additional errors caused by external disturbances

should be taken into account). -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-13

TD

8. Deviations of Automation Functions Timers

Automation Function Timers

Auto-reclose timers tDs, tR, tI 2% +1030 ms CB fail & CB

monitoring timers 2% +1030 msAuxiliary timers tAUX1, tAUX2, tAUX3, tAUX4 2% +1030 ms

Cold load pickup 2% +2040 ms

SOTF 2% +2040 ms

9. DEVIATIONS OF MEASUREMENTS

Measurement Range Deviation

Phase current 0.1 to 40 In Typical 2% at In Earth current 0.01

to 2 Ien Typical 2% at Ien0.05 to 12 Ien Typical 2% at Ien

0.01 to 12 Ien Typical 2% at Ien

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-14 MiCOM P111 Enh

TD

10. PROTECTION SETTING RANGES Note: (A, B, E) available in Model

A, B and E10.1 [50/51] Phase Overcurrent

Phase current Fundamental, RMS

Note: When I> or I>> is associated with an IDMT curve,

the maximum recommended setting is 2 In.10.1.1 Protection Setting Ranges

[50/51] Phase OC Setting Range

Min. Max. Step

I> ? Disabled, Trip, Alarm, Trip with Inrush blocking (A, E),

Trip Latch (A, E ), Trip-Phase A (E), Trip-Phase B (E), Trip-Phase

C (E)I> 0.1 In 4 In (IDMT) 40 In (DMT)

0.01 In

Delay type DT or IDMT (IEC_SI, IEC_VI, IEC_EI, IEC_LTI, IEC_STI,

C02_P20, C08, IEEE_MI, IEEE_VI, IEEE_EI, RXIDG, BPN EDF, RI, RECT,

C02_P40 curve)tI> 0.05 s 200 s 0.01 s

I> TMS 0.02 1.50 0.01

I> TD 0.02 100 0.01

I> Reset Delay Type DT or IDMT (refer to Operation

chapter)DT I> tReset 0.00 s 600 s 0.01 s

K (RI) 0.1 10 0.1

I>> ? Disabled, Trip, Alarm, Trip with Inrush blocking (A,

E), Trip Latch (A, E ), Trip-Phase A (E), Trip-Phase B (E),

Trip-Phase C (E)I>> 0.1 In 4 In (IDMT) 40 In (DMT)

0.01 In

Delay type DT or IDMT (IEC_SI, IEC_VI, IEC_EI, IEC_LTI, IEC_STI,

C02_P20, C08, IEEE_MI, IEEE_VI, IEEE_EI, RXIDG, BPN EDF, RI, RECT,

C02_P40 curve)tI>> 0.05 s 200 s 0.01 s

I>> TMS 0.02 1.50 0.01

I>> TD 0.02 100 0.01

I>> Reset Delay Type DT or IDMT (refer to Operation

chapter)DT I>> tReset 0.00 s 600 s 0.01 s

K (RI) 0.1 10 0.01

I>>> ? Disabled, Trip, Alarm, Trip with Inrush blocking

(A, E), Trip Latch (A, E ), Trip-Phase A (E), Trip-Phase B (E),

Trip-Phase C (E)I>>> 1 In 40 In 0.01 In

tI>>> 0 s 200 s 0.01 s

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-15

TD

10.2 Switch on to fault (SOTF) (Model A, B, E )

Phase current Fundamental only

10.2.1 Protection Setting Ranges

[50/51] SOTF Setting Range

Min. Max. Step

SOTF ? Disabled, Trip, Alarm, Trip with Inrush blocking (A, E),

Trip Latch (A, E )SOTF 1 In 40 In 0.01 In

tSOTF 0 s 600 s 0.01 s

10.3 [49] Thermal Overload Protection (Model N, A, B, E ).

Phase Current: RMS

10.3.1 Protection Setting Ranges

[49] Therm. OL Setting ranges

Therm. OL ? Disabled, Enabled

Itherm 0.1 In 3.0 In 0.01In Te (heating) 1 mn 200 mn 1mn

Tr (cooling) 1 mn 999 mn 1mn

Theta Trip 50% 200% 1%

Theta Reset Ratio 20% 99% 1%

Theta Alarm ? Disabled, Enabled

Theta Alarm 20% 200% 1%

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-16 MiCOM P111 Enh

TD

10.4 [50N/51N] Earth fault protection

Earth fault current Fundamental only

Earth fault current ranges See following table

Note: When IN> are associated to an IDMT curve, the maximum

recommended setting is the highest in the range divided by 20.10.4.1 Protection Setting Ranges

[50/51N] Earth OC Setting Range

Min. Max. Step

High sensitivity current set

Cortec code P111xxx0xxxxxxxxxx (0.01-2Ien)

IN_1 (IN>) 0.01 Ien 0.2 Ien (IDMT) 2.0 Ien (DMT)

0.01 Ien

IN_2 (IN>>) 0.05 Ien 2.0 Ien 0.01 Ien

IN_3 (IN>>>) (E ) 0.05 Ien 2.0 Ien 0.01 Ien Low

sensitivity current setCortec code P111xxx3xxxxxxxxxx (0.05-12Ien)

IN_1 (IN>1) 0.05 Ien 1.2 Ien (IDMT) 12 Ien (DMT)

0.01 Ien

IN_2 (IN>>) 0.3 Ien 12 Ien 0.01 Ien

IN_3 (IN>>>) (E ) 0.3 Ien 12 Ien 0.01 Ien

Wide range current set (available Model E in limited market

version)Cortec code P111xxx4xxxxxxxxxx (0.01-12Ien) special

IN_1 (IN>1) 0.01 Ien 1.2 Ien (IDMT) 12 Ien (DMT)

0.01 Ien

IN_2 (IN>>) 0.01 Ien 12 Ien 0.01 Ien

IN_3 (IN>>>) (E ) 0.3 Ien 12 Ien 0.01 Ien

IN_1 stage? Disabled, Trip, Alarm, Trip with Inrush blocking (A,

E), Trip Latch (A, E )Delay type DT or IDMT (IEC_SI, IEC_VI, IEC_EI, IEC_LTI, IEC_STI,

C02_P20, C08, IEEE_MI, IEEE_VI, IEEE_EI, RXIDG, BPN EDF, RI, RECT,

C02_P40 curve)tIN_1 0.05 s 200 s 0.01 s

K (RI) 0.1 10 0.1

IN_1 TMS 0.02 1.5 0.01

IN_1 TD 0.02 100 0.01

IN_1 Reset Delay Type DT or IDMT (refer to Operation

chapter)DT IN_1 tReset 0.00 s 600 s 0.01 s

IN_2 stage? Disabled, Trip, Alarm, Trip with Inrush blocking (A,

E), Trip Latch (A, E ) -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-17

TD

[50/51N] Earth OC Setting Range

Min. Max. Step

tIN_2 0.00s (0.05 s in Model E P111xxx4xxxxxxxxxx)

200 s 0.01 s

IN_3 stage? (E ) Disabled (E), Trip (E), Alarm (E), Trip with

Inrush blocking (E), Trip Latch (E )tIN_3 (E ) 0 s 200 s 0.01 s

10.5 Negative Sequence Overcurrent Protection (Model E ).

Phase current: Fundamental only

Note: When I2> is associated with an IDMT curve, the maximum

recommended setting is 2 In.10.5.1 Protection Setting Ranges

[46] Neg.Seq. OC Setting ranges

Min. Max. Step

I2> ? Disabled, Trip, Alarm, Trip with Inrush blocking, Trip

LatchI2> 0.1 In 4 In 0.01 In

Delay Type DT or IDMT (IEC_SI, IEC_VI, IEC_EI, IEC_LTI, IEC_STI,

C02_P20, C08, IEEE_MI, IEEE_VI, IEEE_EI, RXIDG, BPN EDF, RI, RECT,

C02_P40 curve)tI2> 0.05 s 200s 0.01s

I2> TMS 0.02 1.5 0.01

I2> Reset Delay Type DT or IDMT (refer to Operation

chapter)DT I2> tReset 0.00 s 600 s 0.01 s 10.6 [46BC] Broken

Conductor Protection (Model E ).Principle used: I2/I1

Functionality available for: (IA or IB or IC) > 10% In

10.6.1 Protection Setting Ranges

[46BC] Broken Conductor Setting ranges

Min. Max. Step

Broken Cond. ? Disabled, Trip, Alarm, Trip with Inrush blocking,

Trip LatchRatio I2/I1 20% 100% 1%

tBCond 0.05 s 600s 0.01s

GLOBAL SETTINGS/ O/C ADVANCED

Setting ranges

Min. Max. Step

[46BC] Brkn.Cond I< Block. 0.1 In 1.00 In 0.01 Ien

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-18 MiCOM P111 Enh

TD

10.7 [50BF] CB Fail Protection

Undercurrent: Fundamental only

10.7.1 Protection Setting Ranges

[50BF] CB Fail Setting ranges

Min. Max. Step

CB Fail ? Disabled, Retrip, Alarm

CB Fail Time tBF 0.1 s 10 s 0.01 s

I< CBF 0.1 In 2 In 0.01 In High sensitivity current setting

P111xxx0xxxxxxxxxx (0.01-2Ien)IN< CBF 0.1 Ien 2 Ien 0.01 Ien Low sensitivity current

setting P111xxx3xxxxxxxxxx (0.05-12Ien)IN< CBF 0.1 Ien 2 Ien 0.01 Ien Wide range e/f current setting

(Model E)P111xxx4xxxxxxxxxx (0.01-12Ien)

IN< CBF 0.1 Ien 2 Ien 0.01 Ien

Block I>? No, Yes

Block IN>? No, Yes

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-19

TD

10.8 Multishot Autoreclose Function (Model E ).

Main shots: 4 independent shots.

External Binary inputs: 5 inputs (CB Faulty External Signal, CB

status 52A, CB status 52B, blocking Autoreclose).Internal programmable trigger from phase and earth fault on all

re-closing cycles.External trigger from logic input (using AUX timer)

Programmable dead times and reclaim time setting.

10.8.1 Multishot auto-recloser Settings

[79] Autoreclose G1/G2 Setting range

Min. Max. Step

Autoreclose ? Disabled, Enabled

Dead time

tD1 0.01 s 600 s 0.01 s

tD2 0.01 s 600 s 0.01 s

tD3 0.1 s 600 s 0.1 s

tD4 0.1 s 600 s 0.1 s

Reclaim time

Reclaim Time tR 0.02 s 600 s 0.01 s

Phase O/C

Fast tripping shots 5 4 3 2 1 Settings

Fast O/C Trip (I>, I>>, I>>>) 0 0 0 0 0 0

relay O/C protection element 1 with Fast Trip delayFast O/C Trip Delay setting 0 ms 9.99 s 10 ms

E/GND

Fast tripping shots 5 4 3 2 1 Settings

Fast E/Gnd Trip (IN_1, IN_2, IN_3)

0 0 0 0 0 0 Time relay E/GND protection element 1 with Fast Trip

delayFast E/Gnd Trip Delay setting 0 ms 9.99 s 10 ms

Close Shot 4 3 2 1 Settings

tI> 0 0 0 0 0 or 1

tI>> 0 0 0 0 0 or 1

tI>>> 0 0 0 0 0 or 1

tIN_1 0 0 0 0 0 or 1

tIN_2 0 0 0 0 0 or 1

tIN_3 0 0 0 0 0 or 1

tAux1 0 0 0 0 0 or 1

tAux2 0 0 0 0 0 or 1

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-20 MiCOM P111 Enh

TD

[79] Autoreclose G1/G2 Setting range

Min. Max. Step

Inhibit Trip on [79] close shot 4 3 2 1 Settings

Inhibit Trip tI> Shot: 0 0 0 0 0 or 1

Inhibit Trip tI>> Shot: 0 0 0 0 0 or 1

Inhibit Trip tI>>> Shot: 0 0 0 0 0 or 1

Inhibit Trip tIN_1 Shot: 0 0 0 0 0 or 1

Inhibit Trip tIN_2 Shot: 0 0 0 0 0 or 1

Inhibit Trip tIN_3 Shot: 0 0 0 0 0 or 1

Inhibit Trip tAux1 Shot: 0 0 0 0 0 or 1

Inhibit Trip tAux2 Shot: 0 0 0 0 0 or 1

Cycles: 0 = no action on auto-recloser: definitive trip 1 = trip

on protection element pick-up, followed by a reclose cycle Inhibit

Trip on Shot: 0 = no inhibit function 1 = auto-reclose without

protection trip (trip command inhibited for protection element — no

trip command from the auto-reclose function).[79] Autoreclose Advanced Settings

Setting range

Min. Max. Step

Ext. CB Faulty Monitoring ? Yes or No

Ext Block via Input ? Yes or No

Start Dead Time on Protection Reset or CB trips

Rolling demand ? Yes or No

Maximum cycle number 2 100 1

Time period Rolling demand 1 mn 24 h 1 mn

Time Inhibit on Close tI 0.0 s 600 s 0.01 s

Signaling Reset No or Close via 79 10.8.2 Further

Time-delaysTimeout upon lack of CB opening signal after a trip: tOpen Pulse

(*) + 0.1 s (not settable)tClose Pulse (*): from 0.1 to 10.00 s in steps of 0.01 s (*)

Setting available in the CIRCUIT BREAKER menu.Timeout upon lack of CB closing signal after a close control and

its associated dead time: tOpen Pulse (*) + 0.1 s (not

settable)tClose Pulse (*): from 0.1 to 10.00 s in steps of 0.01 s (*)

Setting available in the CIRCUIT BREAKER menu. -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-21

TD

11. AUTOMATION CONTROL FUNCTIONS

Note: (ABE) means that the function is available in B and E

model only.11.1 Trip Commands

12. The following protection elements may be set to ‘Disabled’

or ‘Trip’ or ‘Alarm’ or ‘TRIP-Inrush Bl’ (AE) or TRIP-Latch (AE):

tI>, tI>>, tI>>>, tIN_1, tIN_2, tIN_3(E),

tSOTF(ABE), I2>(E), tBrkn Cond(E), tAUX1(ABE), tAUX2(ABE),

tAUX3(ABE), tAUX4(ABE)The trip command is enabled with the following protection

options:TRIP

TRIP with Inrush Blocking (AE)

TRIP with Latch (AE)

For [50/51] o/c protection, additional options:

TRIP Phase A (E)

TRIP Phase B (E)

TRIP Phase C (E)

Thermal Overload can be set to ‘Enabled’ or ‘Disabled’.

CB Fail can be set to ‘Disabled’ or ‘Retrip’ or ‘Alarm’

The first Thermal stage is for Alarm the second one is for

trip.12.1 Latch Functions

Thermal Overload can be latched using the Theta Reset threshold

setting only.12.2 Blocking Logic

The following time-delayed stages may be blocked:

tI>, tI>>, tI>>>, tIN_1, tIN_2, tIN_3,

tI2>(E), tBrkn Cond(E), tSOTF(ABE), Itherm(NABE), tAUX1(ABE),

tAUX2(ABE), tAUX3(ABE), tCB Fail. -

P111Enh/EN TD v1.3

Technical Data (TD) 2-22 MiCOM P111 Enh

TD

12.3 Inrush blocking Logic (Model A and E )

Inrush blocking is based on second harmonic criteria.

The following protection elements may be set to ‘Disabled’ or

‘Trip’ or ‘Alarm’ or ‘TRIP-Inrush Bl'(AE): or TRIP-Latch (AE):

tI>, tI>>, tI>>>, tIN_1, tIN_2, tIN_3(E),

tSOTF(ABE), I2>(E), tBrkn Cond(E), tAUX1(ABE), tAUX2(ABE),

tAUX3(ABE), tAUX4(ABE).The trip command with Inrush Blocking function is enabled with

the following option:Trip-Inrush Bl

There are two methods available:

Permanent action based on a 2nd harmonic ratio threshold (Inrush

Blocking? 1: Yes). The «Inrush Reset Time» setting is available to

this effect.Activation 2nd harmonic after CB closing for defined time period

(Inrush Blocking? 1: Closing). The «Unblock Inrush Time» setting is

available to this effect.For more details please refer to the Application chapter of this

manual.Blocking Inrush Setting range

Min. Max. Step

Blocking inrush No, Yes, Closing

2nd Harmonic Ratio 10% 50% 1%

Inrush Reset Time 0 s 200 s 10 ms

Unblock Inrush Time 0 s 200 s 10 ms 12.4 Logic Selectivity

(Model E )Logic selectivity 1 and logic selectivity 2: This function is

used to assign a time-delay to the protection elements mapped to

the Log Sel inputs.Logic Selectivity G1/G2 Setting range

Min. Max. Step

Sel1? Disabled or Enabled

t Sel1 0 s 600 s 10 ms

Sel2? Disabled or Enabled

t Sel2 0 s 600 s 10 ms

The inputs can be mapped to the following protection elements:

tI>>, tI>>>, tIN>>, tIN>>> (E).12.5 Output Relays

Assignable functions: Protection Trip, Protection Trip (pulse),

Trip CB Order, Close CB Order, Alarm, I>, I>>,

I>>>, SOTF(ABE), IN_1, IN_2, IN_3(E), I2>(E), Start

Broken Conductor(E), AUX1(ABE), AUX2(ABE), AUX3(ABE), AUX4(ABE),

AUX5(ABE), AUX6(ABE), tI>, tI>>, tI>>>,

tSOTF(ABE), tIN_1, tIN_2, tIN_3(E), tI2>(E), tBrkn Cond(E),

Thermal Trip(NABE), Thermal Alarm(NABE), CB Fail, tAUX1(ABE),

tAUX2(ABE), tAUX3(ABE), tAUX4(ABE), [79] in Progress(E), [79] Final

Trip(E), [79] Lockout(E), [79] Blocked(E), [79] Success. (E), CB

Alarm(AE), tCB Faulty(E), Active Setting Group .12.6 Latch of the auxiliary Output Relays

All output relays (WD not included) can be latched.

12.7 Reverse Output Relay Logic

All logic of the output relays can be reversed.

Note: Reverse logic means that if a function assigned to outputs

is disabled the contact is closed. If the function is enabled the

contact is opened. -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-23

TD

12.8 Inputs (Model A, B and E )

12.8.1 Input Assignation

A single function or multiple automation functions can be

assigned to 4(AB) or 8(E) logic inputs:None, Maintenance Mode(AE), Reset Latched Signaling(ABE), Reset

Latched Outputs(ABE), Block tI>(ABE), Block tI>>(ABE),

Block tI>>>(ABE), Block tSOTF(ABE), Block tIN_1(ABE),

Block tIN_2(ABE), Block tIN_3(E), Block tI2>(E), Block tBrkn

Cond(E), Block Itherm(ABE), Block AUX1(ABE), Block AUX2(ABE), Block

AUX3(ABE), Block AUX4(ABE), Block [79](E), Sel1 tI>>(E), Sel1

tI>>>(E), Sel1 tIN_2(E), tIN_3(E), Sel2 tI>>(E),

Sel2 tI>>>(E), Sel2 tIN_2(E), tIN_3(E), AUX1(ABE),

AUX2(ABE), AUX3(ABE), AUX4(ABE), AUX5(ABE), AUX6(ABE), Cold Load

PU(ABE), Start tBF(AE), CB status 52a(ABE), CB status 52b(ABE), CB

Faulty External Signal(ABE), Setting Group 2(ABE), Manual

Close(ABE), Manual Trip(ABE), Trip Circuit Supervision (AE), Reset

Theta Value(ABE), Start Disturbance Recorder(AE), Local CTRL

Mode(AE), Time Synchronization(E).12.8.2 Reverse Input Logic

The logic of the inputs can be reversed: Input L1 to L4 (model

A, B) or L1 to L6 (model E)Note: Reverse logic means that if an input is energized, the

function assigned to this input is disabled. If the input is not

energized, the function is enabled.12.9 LEDs

Assignable functions: Protection Trip, Alarm, Start Phase A,

Start Phase B, Start Phase C, I>, I>>, I>>>,

SOTF(ABE), IN_1, IN_2, IN_3(E), I2>(E), Start Broken

Conductor(E), AUX1(ABE), AUX2(ABE), AUX3(ABE), AUX4(ABE),

AUX5(ABE), AUX6(ABE), tI>, tI>>, tI>>>,

tSOTF(ABE), tIN_1, tIN_2, tIN_3(E), tI2>(E), tBrkn Cond(E),

Thermal Trip(NABE), Thermal Alarm(NABE), CB Fail, tAUX1(ABE),

tAUX2(ABE), tAUX3(ABE), tAUX4(ABE), [79] in Progress(E), [79] Final

Trip(E), [79] Lockout(E), [79] Blocked(E), [79] Success.(E), Local

CTRL Mode (AE), CB Alarm(AE), Maintenance Mode(AE), tCB

Faulty(ABE), Active Setting Group.12.10 Latch of the auxiliary Output Relays

All output relays (WD not included) can be latched.

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-24 MiCOM P111 Enh

TD

12.11 Auxiliary Timers (available in B, A and E )

Auxiliary timers G1/G2 Setting range

Min. Max. Step

Aux1 ? Disabled (ABE), Trip(ABE), Alarm(ABE), Trip with Inrush

blocking (AE), Trip with Latching,(AE) Load Shedding (LS) (E), AR

after LS Hi (Hi state activates) (E), AR after LS Lo (Lo state

activates) (E)Time-delay tAux1 0 600 s 10 ms

Aux2 ? Disabled (ABE), Trip(ABE), Alarm(ABE), Trip with Inrush

blocking (AE), Trip with Latching,(AE) Load Shedding (LS) (E), AR

after LS Hi (Hi state activates) (E), AR after LS Lo (Lo state

activates) (E)Time-delay tAux2 0 600 s 10 ms

Aux3 ? Disabled (ABE), Trip(ABE), Alarm(ABE), Trip with Inrush

blocking (AE), Trip with Latching,(AE) Load Shedding (LS) (E), AR

after LS Hi (Hi state activates) (E), AR after LS Lo (Lo state

activates) (E)Time-delay tAux3 0 600 s 10 ms

Aux4 ? Disabled (ABE), Trip(ABE), Alarm(ABE), Trip with Inrush

blocking (AE), Trip with Latching,(AE) Load Shedding (LS) (E), AR

after LS Hi (Hi state activates) (E), AR after LS Lo (Lo state

activates) (E)Time-delay tAux4 0 600 s 10 ms 12.12 Cold Load Pickup

Cold Load PU G1/G2 Setting range

Min. Max. Step

Cold Load PU ? Disabled or Current+Input or Input (AE)

Cold load PU Level 20% 999% 1%

Cold load PU tCL 0s 6000 s 100 ms

CLPU I> Yes or No

CLPU I>> Yes or No

CLPU I>>> Yes or No

CLPU IN_1 (IN>) Yes or No

CLPU IN_2 (IN>>) Yes or No

CLPU IN_3 (IN>>>) (E) Yes or No

CLPU Brkn Cond (E) Yes or No

CLPU Itherm (NABE) Yes or No

CLPU I2> (E) Yes or No

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-25

TD

12.13 Circuit Breaker

12.13.1 CB Time Setting Ranges

CB Control Time Model Setting range

Min. Max. Step

tOpen Pulse min All models 0.1 s 10 s 0.01 s

tClose Pulse All models 0.1 s 10 s 0.01 s

Time-delay for Close A and E 0.0 s 200 s 0.01 s 12.13.2

Time-delay for Faulty CB External Signal (Model A, B and E )CB Faulty External Monitoring

Setting range

Min. Max. Step

tCB FLT ext 1 s 200 s 1 s 12.13.3 Remote Control Mode (Model A

and E )Remote Control Mode Setting range

Remote CTRL Mode Remote only Remote + Local

12.13.4 Unblock SOTF Time pulse after CB Close (Model A , B and

E )Unblock SOTF Time Setting range

Min. Max. Step

52 Unblock SOTF Time 0 s 200 s 0.01 s 12.13.5 Trip Circuit

Supervision Setting Ranges (Model A and E )TC Supervision Setting range

Min. Max. Step

TC Supervision ? No or Yes or Yes-52A

TC Supervision tSUP 0.1 s 10 s 0.01 s 12.13.6 Circuit Breaker

Control and Monitoring Setting Ranges (Model A and E )CB Supervision Setting range

Min. Max. Step

CB Time Supervision? Yes or No

CB Open time 0.01 s 10 s 0.01 s

CB Close time 0.01 s 10 s 0.01 s

CB Diagnostic ? Yes or No

Max CB Open NB 1 50000 1

Amps(n) 0.1 MA^n 6535.5 MA^n

0.1MA^n

n 1 2 1

-

P111Enh/EN TD v1.3

Technical Data (TD) 2-26 MiCOM P111 Enh

TD

13. RECORDING FUNCTIONS 13.1 Event Records

(not available in model L without RS485)

Capacity 200 events

Time-tag 1 millisecond

Triggers Any selected protection alarm and threshold Logic input

change of state Setting changes Self test events13.2 Fault Records

Capacity 20 faults

Time-tag 1 millisecond

Triggers Any selected protection which trip CB

Data Fault date Protection thresholds Setting Group AC inputs

measurements (RMS) Fault measurements13.3 Instantaneous Recorder (Model E )

Capacity 5 starting information (instantaneous)

Time-tag 1 millisecond

Triggers Any selected protection which trip CB

Data Date, hour origin (any protection)

13.4 Alarm Recorder

Capacity 5 alarm information

Time-tag 1 millisecond

Triggers Any selected protection which is selected for signaling

only (set to Alarm)Data Date, hour origin (any protection alarm)

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-27

TD

13.5 Disturbance Records (Model A and E )

13.5.1 Triggers, Data, Setting Ranges

Disturbance Records Total record: up to 3s, but not more than 5

recordsTriggers Any selected protection alarm and threshold, logic

input, remote commandData AC input channels digital input and output states frequency

valueDefault value Setting range

Min. Max. Step

Pre-fault Time 0.1 0.1 2 0.01

Post-fault Time 0.1 0.1 2 0.01

Max duration time 3 0.10 3 0.01

Disturb rec Trig on Inst on Trip or on Inst.

Trigger Protection selected for tripping, Logic input (Start

Distur.R.) -

P111Enh/EN TD v1.3

Technical Data (TD) 2-28 MiCOM P111 Enh

TD

14. COMMUNICATION (in Model L : option)

Type Port

Physical Link Connectors Data Rate Comms. mode Protocol

RS485 (in L option)

Screened twisted pair

Screws or snap-on

4.8 or 9.6 or 19.2 or 38.4 (default:19.2 kbit/s)

Data Bit: 8 Stop bit: 1/ 2 Parity: None/Odd/Even Adress: 1 to

254Modbus RTU, IEC60870-5-103 (selectable in menu)

USB USB2.0 PC: type A male P111: type mini B male

115.2 kbits/s (fixed)

Data Bit:8 Stop bit: 1 Parity: None Adress: 1

Modbus RTU

-

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-29

TD

15. CURVES 15.1 General

Although the curves tend towards infinite when the current

approaches Is (general threshold), the minimum guaranteed value of

the operating current for all the curves with the inverse time

characteristic is 1.1 Is (with a tolerance of 0.05 Is).15.1.1 Inverse Time Curves

The first phase (or earth) overcurrent stage can be selected

with an inverse definite minimum time (IDMT) characteristic. The

time-delay is calculated using a mathematical formula.In all, there are eleven IDMT characteristics available.

The mathematical formula applicable to the first ten curves

is:+

= cP

GsG

kTMSt

Where:

t Operation time

k, c, , P Constant (see table)

G Value of measured current

Gs Value of the programmed threshold (pick-up value) TMS Time

multiplier setting (for IEC: TMS; IEEE: TD)Type of curve (according to IEC60255-151 std definition)

Standard k c P

IEC Standard inverse (SI) IEC/A 0.14 0 0.02 1

IEC Very inverse (VI) IEC/B 13.5 0 1 1

IEC Extremely inverse (EI) IEC/C 80 0 2 1

Long time inverse (LTI) IEC 120 0 1 1

FR Short time inverse (STI) FR 0.05 0 0.04 1

US Short time inverse C02 P20 0.02394 0.01694 0.02 1

US Short time inverse C02 P40 0.16758 0.11858 0.02 1

Long time inverse C08 5.95 0.18 2 1

Moderately Inverse IEEE (IEC/D) 0.0515 0.114 0.02 1

Very inverse IEEE (IEC/E) 19.61 0.491 2 1

Extremely inverse IEEE (IEC/F) 28.2 0.1217 2 1

UK Rectifier protection RECT 45900 0 5.6 1

BNP (EDF) EDF 1000 0.655 2 1

RI -4.2373 0 -1 1.43644

Note: For RI curve the equation is valid for the range: 1.1 I/Is

20 -

P111Enh/EN TD v1.3

Technical Data (TD) 2-30 MiCOM P111 Enh

TD

RXIDG Curves

RXIDG curves can be selected on P111Enh Model E with wide earth

current (corresponding to Cortec model number P111xxx4xxxxxxxxxx

)The first earth thresholds can be selected with dedicated RXIDG

curves.The curves available follow the formula:

t = 5.8 1.35 * ln ( 1/ (k * Is/I))

Where:

t = tripping time

k = coefficient (from 0.3 to 1, by steps of 0.01)

Is = value of the programmed threshold (Pick-up value)

I = value of measured current

In order to be compliant with the Netmanagement specifications

the relay must be used with:An earth current range 0.01 Ion to 12 Ien

A rated current wiring 1A

A core balanced CT with a ratio 25/1.

15.1.2 Reset Timer

The first phase and earth overcurrent stages and the second

phase overcurrent stage are provided with a timer hold facility: «t

Reset».The value that is set for this reset timer corresponds to the

minimum time during which the current value needs to be lower than

95% of the phase (or earth) threshold before the corresponding

phase (or earth) time-delay is reset.Note: There is an exception to this rule when the protection

triggers. In fact, in that case, the time-delays (tI> and

tIe>) are immediately reset.The value of the Reset Timer depends on the type of timer

associated with the pick-up of the first phase (or earth)

stage.Type of timer associated with the first & second phase O/C

stages and the first earth fault stageReset Timer

DMT Reset characteristic IDMT characteristic

DMT, Rectifier, LTI, STI, Rectifier, BNP EDF, RXIDG

Settable from 0 to 600 ms Not available. If IDMT is selected:

reset timer is set to 0s (see table below: K=0)IDMT IEC or RI Settable from 0 to 600 ms Based on RTMS value

(refer to Operation chapter)IDMT IEEE or CO Settable from 0 to 600 ms Based on RTD value

(refer to Operation chapter)Reset timer:

The first phase, earth and negative sequence overcurrent stages

are provided with a timer hold facility: «t Reset». -

Technical Data

P1111Enh/EN TD v1.3 MiCOM P111Enh (TD) 2-31

TD

It may be set to a definite time value or to an inverse definite

minimum time characteristic (IEC/IEEE/ANSI curves only). This may

be useful in certain applications, for example when grading with

upstream electromechanical overcurrent relays that have inherent

reset time-delays.The second and third earth fault stages have only a definite

time reset.A possible situation where the reset timer may be used is to

reduce fault clearance times where intermittent faults occur.An example may occur in a cable with plastic insulation. In this

application it is possible that the fault energy melts the cable

insulation, which then reseals after clearance, thereby eliminating

the cause for the fault. This process repeats itself to give a

succession of fault current pulses, each of increasing duration

with reducing intervals between the pulses, until the fault becomes

permanent.When the reset time of the overcurrent relay is set to its

minimum, the relay will be repeatedly reset and will not be able to

trip until the fault becomes permanent. By using the reset timer